Decal Kits

Ohio Sheriff

Safety Markings

Badge Decals

K9 and other Misc

Fire/EMS

School Bus Markings

Boat / Truck Numbers

More Available

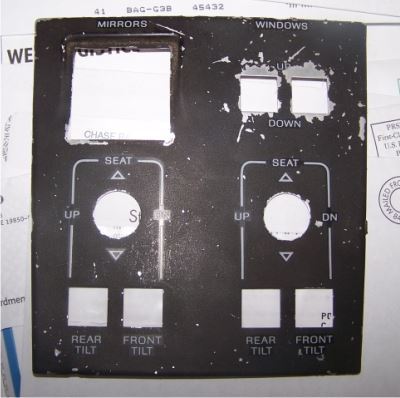

Here's a picture of the plate starting out.

I received the plate already removed but I have removed them in the past. I use a 3M adhesive remover to loosen up the glue. I'm at kind of an advantage here because this is a product that we use all the time in the shop. NAPA also sells a similar product that works just as good. Squirt it under the edge of the plate and let it soften up the glue then pull it off slowly or even use a putty knife to get under it. The trick is not to warp or dent the plate.

Once off I put the plate in a small tray and cover it in acetone and let it soak for ten or fifteen minutes. This softens the paint up then I used a small brass bristle brush and the paint comes right off. You can also use paint stripper to do the same. Here's what it looks like at this point.

You can see and even feel the indention where the original markings where screen printed on. I normally would sand them off with something like 400 grit to get it smooth. The smoother the surface the better the decal will look. On this plate I chose to leave these marks intact. I wanted to use them as reference points to see how close my markings were to the factory location.

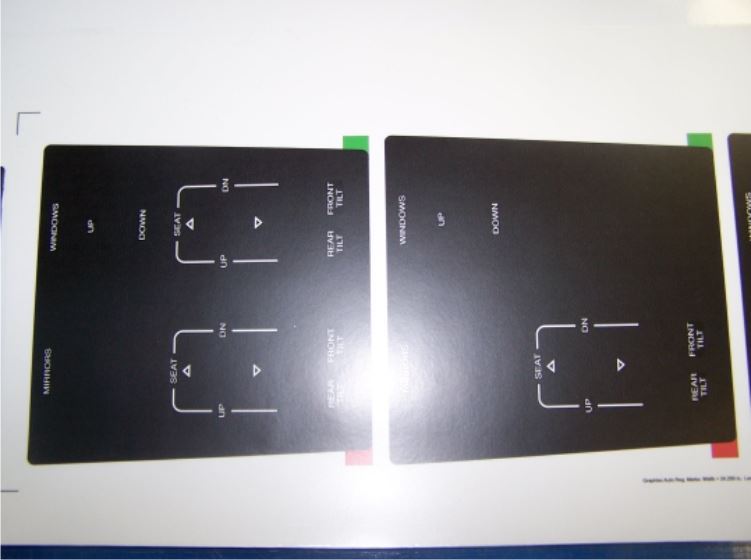

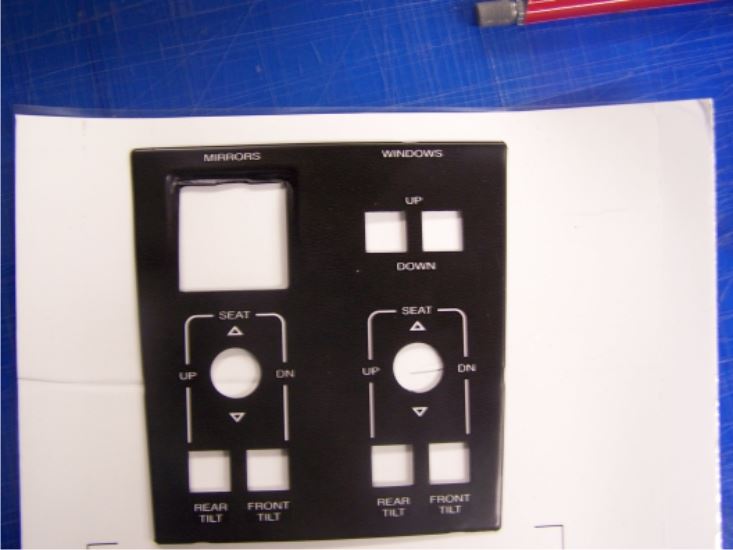

Here is a picture of the decals before installed.

They are cut to the edge of the printed area. The printed area will overlap the plate by about 1/8" all the way around. Remove the decal from the backing and lay it on a clean surface adhesive side up. Center the plate on the decal and allow it to lightly adhere so you can pick it up and turn it over to apply the decal. The material used is actually wrap material so it is pretty forgiving to install. just use your thumbs to push it in place. A heat gun or hair dryer will help to get it to lay down on the switch area and the edges of the plate. Next use an x-acto knife or similar to trim out the switch holes. You should end up with something like this.

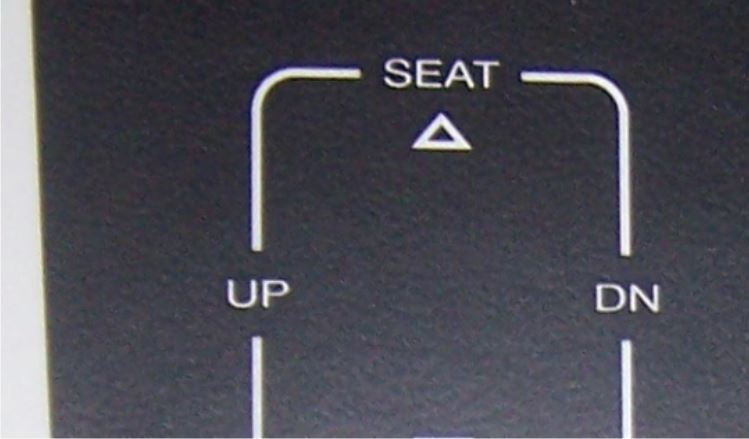

Here is a closeup of the decal. We tried to get as close as possible to the look of the original finish.